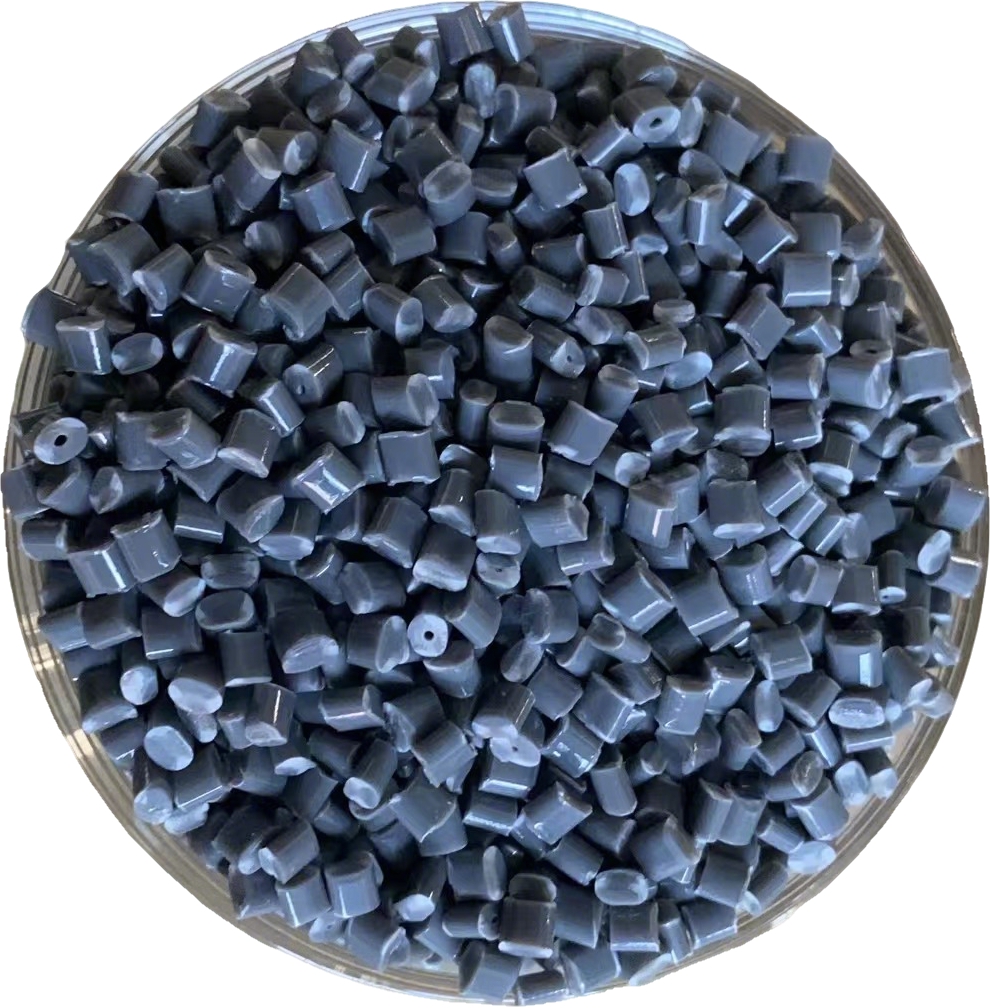

Weather-Resistant ABS WA-2031: Super Weather Resistance, Aging Resistance, Long-Term Stability and Durability

Weather-Resistant ABS (Gray) is an engineering plastic optimized through professional modification technology. Based on ABS resin, it is added with special ultraviolet absorbers, hindered amine light stabilizers and weather-resistant additives, which not only retains the inherent characteristics of ABS resin such as "toughness, hardness and rigidity", but also has excellent outdoor weather resistance. At the same time, it is matched with a classic gray appearance to achieve the dual value of "reliable performance + appearance adaptability". It is widely suitable for the processing needs of various products in outdoor, semi-outdoor and harsh environments, and completely solves the pain points of ordinary ABS such as brittleness, discoloration and cracking when used outdoors.

I. Core Product Features

1. Super Weather Resistance and Aging Resistance, Long-Term Stability and Durability

With precise modified formula, it can effectively resist the erosion of natural environments such as ultraviolet rays, high and low temperature cycles, rain and snow, humidity and heat, and salt spray. After 5000 hours of QUV ultraviolet aging test, the color difference △E ≤ 1.2, the gloss retention rate is more than 85%, and there is no powdering, cracking or brittleness. The temperature resistance range is -30℃ to 80℃, which can adapt to different climate zones in the north and south. After long-term outdoor use (more than 5 years), it can still maintain stable mechanical properties and appearance color, greatly extending the service life of products and reducing maintenance and replacement costs. At the same time, it has excellent acid rain resistance and corrosion resistance, and no rust or blistering occurs after 1500 hours of salt spray test, which is suitable for use in coastal high-salt-spray environments.

2. Classic Gray Texture, Suitable for Diverse Scenarios

Adopting integral coloring technology, the gray color is uniform, full, free of impurities and color difference. It can be adapted to standard gray numbers such as RAL7040 according to requirements, and the surface can be treated with high gloss, matte, frosted and other processes, which has both industrial simple aesthetics and practicality. The gray color is versatile and durable, not easy to get dirty, and can be perfectly integrated into various product design styles such as automotive exterior parts, outdoor home appliances, municipal facilities and communication equipment. It not only meets the needs of appearance decoration, but also avoids the disadvantages of light colors being easy to turn yellow and dark colors being easy to absorb heat, taking into account both appearance and practicality. It is especially suitable for mass production needs that require high consistency of appearance.

3. Excellent Mechanical Properties, Tough and Durable

It inherits the inherent advantages of ABS resin (acrylonitrile-butadiene-styrene terpolymer), with high rigidity, high toughness and good impact resistance. The tensile strength is ≥ 42MPa, the low-temperature (-30℃) impact strength is ≥ 18kJ/m², and the elongation at break is ≥ 25%, which is not easy to be damaged or deformed, and can withstand daily collisions, transportation bumps and complex outdoor stress scenarios. At the same time, it improves dimensional stability, with a molding shrinkage rate of ≤ 0.6% and a low linear expansion coefficient. The processed products have precise dimensions and are not easy to warp or deform, which is suitable for the production of products requiring high dimensional accuracy.

4. Easy to Process and Mold, Suitable for Multiple Processes

The melt flow rate can reach 25g/min (220℃, 10Kg), with excellent fluidity. It can be easily adapted to various processing technologies such as injection molding, extrusion, blister molding, stamping, CNC laser cutting and hot bending. The molding cycle is short, the demolding is smooth, and it is not easy to have problems such as mold sticking and material shortage. The scrap rate can be controlled within 3%, which greatly improves production efficiency. At the same time, it has good spray adhesion and electroplating performance, supports various surface treatment processes, and can be secondary processed according to requirements to meet the personalized design needs of different products. No additional optimization of processing technology is required, reducing production costs and technical thresholds.

5. Environmental Protection and Safety, Compliance with Industry Standards

The product does not contain harmful substances such as decabromodiphenyl ether and tetrabromobisphenol A, has no peculiar smell, and has low content of small molecular volatile substances. It complies with international environmental protection standards such as RoHS and REACH, as well as various industry environmental protection requirements. It can be used in scenarios with high environmental protection requirements such as home appliances, outdoor children's products and surface components of medical equipment, which is safe and harmless. At the same time, it has a recyclability rate of 92%, practicing the concept of green production and reducing resource waste.

II. Applicable Application Scenarios

Relying on its comprehensive advantages of weather resistance, toughness, beauty and easy processing, it is widely used in many fields, especially suitable for outdoor and semi-outdoor scenarios, including:

Automotive field: Rearview mirror housings, door trim parts, spoilers, rain gutters, outdoor air conditioning components and other automotive exterior parts and peripheral accessories, which can resist outdoor wind, rain and sun, and maintain long-term beauty and stable performance;

Outdoor home appliance field: Shells and structural parts of outdoor air conditioning units, photovoltaic inverter protective cases, outdoor refrigerators, outdoor fans, terrace barbecues, etc., which are suitable for complex outdoor environments and extend the service life of home appliances;

Communication equipment field: 5G outdoor fiber distribution boxes, outdoor monitoring equipment housings, communication base station peripheral accessories, etc., which have excellent moisture resistance, water resistance, dust resistance, corrosion resistance and aging resistance, ensuring stable operation of equipment;

Municipal and outdoor facilities field: Components of urban bus station canopies, shells of outdoor fitness equipment, highway guardrail connectors, outdoor charging pile housings, traffic sign components, park tables and chairs, etc., which are suitable for various climate environments, reduce maintenance costs, and improve the durability and beauty of municipal facilities;

Other fields: Outdoor toys, leisure equipment, lightweight components around ships, outdoor auxiliary accessories of medical equipment, etc., which take into account safety, weather resistance and processing convenience, meeting diverse production needs.

III. Processing Technology Reference

This product is suitable for various conventional processing technologies. Combined with its melt flow characteristics and weather-resistant modification features, referring to the following process parameters can optimize processing effects, reduce molding defects, and ensure that product performance and appearance meet standards (specific parameters can be adjusted according to equipment model and product structure):

1. Injection Molding Process (Most Commonly Used, Suitable for Various Housings and Structural Parts)

Drying treatment: The raw materials need to be dried before processing, with a temperature of 80-90℃ and a drying time of 2-3 hours. The water content should be controlled below 0.1% to avoid defects such as bubbles and shrinkage cavities after molding;

Barrel temperature: 180-200℃ for the front section, 200-220℃ for the middle section, 210-230℃ for the rear section, and 210-225℃ for the nozzle (excessively high temperature may lead to raw material degradation and affect weather resistance; excessively low temperature may cause material shortage and weld lines);

Mold temperature: 40-60℃, which can be adjusted according to product size (take the upper limit for large and complex parts) to ensure smooth demolding, reduce warpage and deformation, and ensure uniform gray color without flow marks;

Injection pressure: 60-90MPa, injection speed: medium speed (30-50mm/s) to avoid flash caused by high-speed injection and obvious weld lines caused by low speed;

Holding pressure: 40-60MPa, holding time: 10-30s, cooling time: 20-60s (adjust according to product thickness) to ensure dense products and precise dimensions.

IV. Quality Assurance and After-Sales Service

The product adopts high-quality base materials and imported weather-resistant additives, and is fully controlled by the ISO9001 quality management system. Each batch of products has passed multiple tests such as weather resistance, mechanical properties, color consistency and environmental protection, and a complete test report is provided. We are equipped with a professional technical team, which can provide customized process optimization schemes according to customers' product structure and processing equipment, and solve various problems encountered in the processing process. At the same time, we provide perfect after-sales guarantee. In case of product quality problems, we can timely communicate about return, replacement and technical rectification matters to help customers achieve efficient production.