+86053268965111

electric panel, weather-resistant

Television back cover material

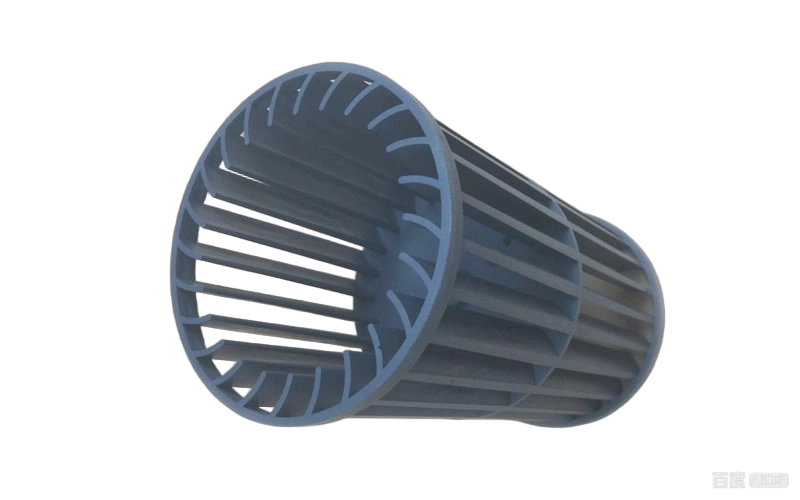

Material of axial flow fan

Analysis of Automotive Door Panel MaterialsThe automotive door panel is one of the most complex interior components, integrating a high degree of functionality. It must balance aesthetics and tactile comfort withcrash safety (energy absorption), lightweighting, weather resistance, and environmental standards.The following is a detailed breakdown of the mainstream materials used in "Door Panel II" (structural components and decorative inserts):1. Door Carrier / SubstrateThis serves as the "backbone" of the door panel, supporting all switches, speakers, and armrests.Mainstream Materials: Modified PP (Polypropylene)PP+T20/T30:Polypropylene with 20% or 30% Talc filler. It offers excellent dimensional stability and low shrinkage rates.Long Glass Fiber Reinforced PP (PP+LGF):Commonly used in high-end models; it provides extreme strength and lightweighting, effectively replacing metal carriers to enhance structural integrity during collisions.Advantages:Low cost, low density (lightweight), an

Analysis of Automotive Bumper MaterialsAn automotive bumper is a critical safety and aesthetic component. Its material selection is driven by a balance oflightweighting, energy absorption (pedestrian protection), low cost,andcoating quality.Today, over 90% of passenger car bumpers are made fromModified Polypropylene (PP). Below is a detailed breakdown of the components and materials:1. Bumper Fascia (The Outer Shell)This is the visible exterior part that requires high impact resistance and a perfect surface finish.Mainstream Material: PP + EPDM + TD20 (Toughened & Filled PP)PP (Polypropylene):The base resin provides excellent processability and low density for weight reduction.EPDM (Rubber):Acts as a toughening agent. It ensures the bumper remains flexible and does not shatter into sharp shards during an impact, even at low temperatures.TD20 (20% Talc Filler):Increases stiffness and dimensional stability. It prevents the bumper from warping in the heat and controls the thermal expa

front bumper of the car

MINI New Energy Vehicle Door Panel

Beijing Auto Works Co., Ltd. was established in 1951 and is the second large-scale automobile enterprise created after the founding of the People's Republic of China. In 1958, it was personally named by Chairman Zhu De. It is the pioneer of China's automobile industry and the cradle of Beijing's automobile industry. Over the past 73 years, it has made tremendous contributions to the country's economic development and national defense construction. Its 212 off-road vehicles have accumulated a total of 2 million in production and sales, influencing several generations of Chinese people and creating a legendary national brand in the Chinese automobile industry. In 2020, Beijing Auto Works Co., Ltd. underwent a comprehensive capital restructuring and relocated to Qingdao, investing 15.2 billion yuan to build the Qingdao headquarters base, and at the same time, an engine production facility was also built.