Analysis of Automotive Bumper Materials

An automotive bumper is a critical safety and aesthetic component. Its material selection is driven by a balance of lightweighting, energy absorption (pedestrian protection), low cost, and coating quality.

Today, over 90% of passenger car bumpers are made from Modified Polypropylene (PP). Below is a detailed breakdown of the components and materials:

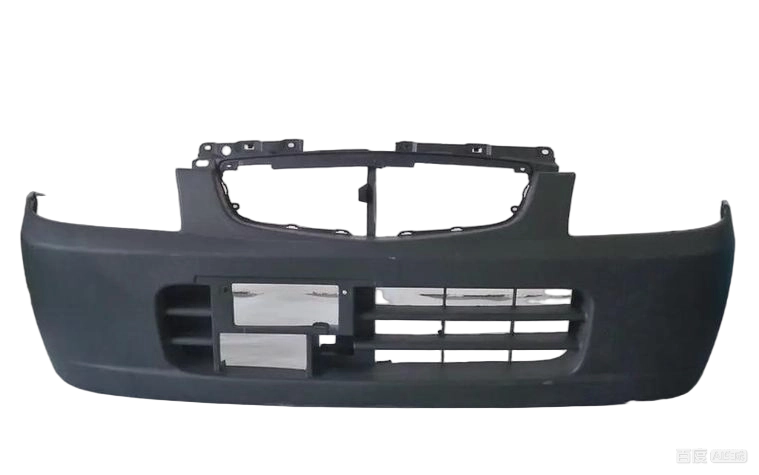

1. Bumper Fascia (The Outer Shell)

This is the visible exterior part that requires high impact resistance and a perfect surface finish.

Mainstream Material: PP + EPDM + TD20 (Toughened & Filled PP)

PP (Polypropylene): The base resin provides excellent processability and low density for weight reduction.

EPDM (Rubber): Acts as a toughening agent. It ensures the bumper remains flexible and does not shatter into sharp shards during an impact, even at low temperatures.

TD20 (20% Talc Filler): Increases stiffness and dimensional stability. It prevents the bumper from warping in the heat and controls the thermal expansion rate for better paint adhesion.

Advantages: Low cost, easy to recycle, excellent chemical resistance, and great paintability.

2. Energy Absorber (Shock Absorber)

Located between the fascia and the reinforcement beam, this part absorbs energy during low-to-medium speed impacts and protects pedestrians' legs.

Mainstream Material: EPP (Expanded Polypropylene)

Characteristics: High energy absorption-to-weight ratio and excellent recovery (elasticity).

Advantages: Tougher than traditional EPS (Styrofoam), it remains intact after impact and is 100% recyclable.

3. Bumper Reinforcement Beam

The "skeleton" of the bumper system, responsible for transferring impact energy to the vehicle’s chassis.

Mainstream Materials:

Ultra-High-Strength Steel (UHSS): Typically hot-stamped steel; used widely for its extreme rigidity.

Aluminum Alloy: Common in mid-to-high-end vehicles for significant weight reduction and high energy absorption efficiency.

Composite Materials (GMT or Long Glass Fiber PP): Used in some EVs or compact cars to achieve maximum lightweighting.

4. Brackets and Grilles

Used for mounting the bumper to the body or providing air intake.

Mainstream Materials: ABS or PC/ABS

ABS: Used for grilles due to its high gloss and ease of electroplating (chrome finish).

POM (Acetal): Used for clips and fasteners due to its high strength and wear resistance.

Core Performance Metrics

Component | Primary Material | Key Requirements |

Bumper Fascia | Modified PP (PP+EPDM+TD20) | Impact resistance, low-temp ductility (-40°C), paintability |

Energy Absorber | EPP | Lightweight, high energy absorption, multi-impact durability |

Reinforcement Beam | Aluminum / Hot-stamped Steel | High yield strength, anti-deformation |

Mounting Brackets | PA6+GF or PC/ABS | Rigidity, thermal stability, connection strength |

Industry Trends

Plastic Replacing Steel: Reinforcement beams are shifting from steel to Aluminum or Long Glass Fiber Reinforced PP (PP+LGF) to save weight.

Paint-Free Materials: To reduce environmental impact (VOCs), some manufacturers use High-Gloss Mold-In-Color PP, which achieves a metallic or "piano black" look directly from the mold without painting.

Sensor Integration: Modern bumpers house ADAS sensors (radar/ultrasonic). Materials must now meet specific Electromagnetic Wave Permeability standards to ensure sensor accuracy.