1. Core Structure & Working Principle

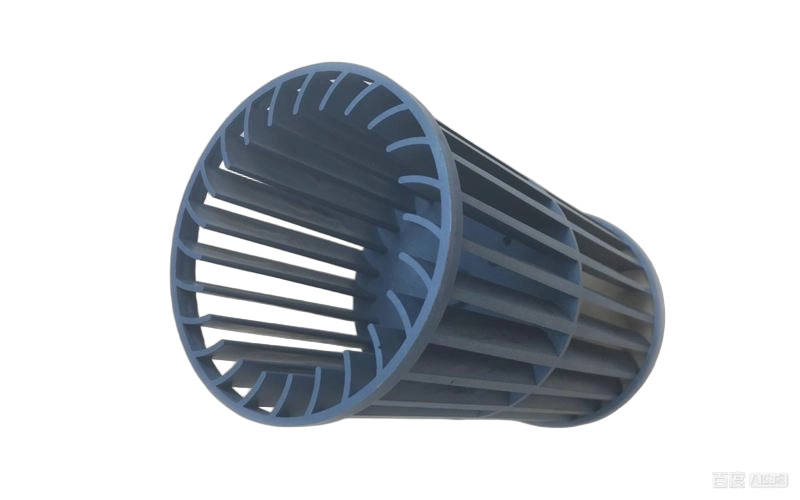

A Cross Flow Fan consists of a long, cylindrical impeller (multi-blade rotor), a scroll housing (vane), and a driving motor.

Working Principle: Unlike axial fans where air flows parallel to the shaft, in a cross flow fan, the air enters the impeller from one side, passes through the interior of the rotor, and is discharged on the opposite side in a tangential direction.

Airflow Pattern: It produces a wide, uniform, and two-dimensional "curtain" of air, which is much smoother than the turbulent, helical flow produced by axial fans.

2. Key Product Advantages

Uniform Air Distribution: Because of its long cylindrical shape, it can deliver an even flow of air across the entire width of the outlet.

Ultra-Low Noise: Since the impeller is larger in diameter and operates at lower speeds to move large volumes of air, it avoids the high-pitched "whirring" associated with smaller fans.

Slim & Compact Profile: Its long, narrow shape allows it to fit into shallow or flat spaces where a circular fan would be too bulky.

Long Throw: The airflow remains stable over a longer distance, making it ideal for creating air barriers.

3. Typical Applications

Cross flow fans are the preferred choice when quiet operation, wide coverage, and space efficiency are required.

A. Consumer Electronics & Appliances

Air Conditioning Units (Indoor): The most common use. The long impeller allows for quiet, wide-angle cooling in wall-mounted or floor-standing ACs.

Tower Fans & Heaters: Used to create a vertical breeze that covers the height of a person's body.

Dishwashers & Ovens: Used for localized cooling and steam dissipation in slim cavities.

B. Commercial & Industrial Use

Air Curtains: Installed above entrances in malls or cold storage to create a high-velocity "air wall" that prevents insects, dust, and temperature loss.

Elevator Ventilation: Provides quiet and consistent air exchange for passengers.

Transformer & Cabinet Cooling: Used to cool long rows of electrical components or heat sinks.

C. Precision Cooling

LED Displays: Cooling large, flat screen modules without adding significant thickness to the display.

Data Projectors: Efficiently moving heat away from internal optics while maintaining low noise levels.

4. Technical Comparison

Feature | Cross Flow Fan | Axial Fan | Centrifugal Fan |

Airflow Type | Wide, Laminar (Curtain) | Concentric (Spiral) | Targeted (Spot) |

Pressure | Low to Medium | Low | High |

Noise Level | Very Low | Medium to High | High |

Space Profile | Rectangular/Long | Circular/Boxy | Scroll/Bulky |

5. Selection Guide

When specifying a cross flow fan, consider the following parameters:

Impeller Dimensions: Length ($L$) and Diameter ($D$) are the primary factors for airflow volume.

Motor Type: DC Brushless motors are recommended for applications requiring variable speed control and maximum energy efficiency.

Material: Aluminum alloy is used for high-temperature environments (like heaters), while Reinforced Plastic is used for standard consumer goods.